Die Cut Products

Machinery:

Clicker Presses, Traveling Head Presses, Full Beam Presses. Automatic Feed Traveling Head Presses

Materials:

Rubber, Sponge, Felt, Plastic, PTFE, Cork, Compressed sheet and others.

Akron Gasket has been Die Cutting for over 40 years with the experience needed to get the job done quickly and efficiently.

DieLess Cutting

Akron Gasket has now brought on line 2 DieLess Cutter systems. This enables us to cut prototype and fabricated parts without the expense of tooling.

Akron Gasket can cut most materials up to 3/4″ thick and with a table size of 60″ x 120″.

Materials:

Rubber, Sponge, Felt, Plastic, PTFE, Cork, Compressed sheet and others

This machine enables us to have a quicker turn around time with extreme accuracy as well as the flexibility to modify the size and shape.

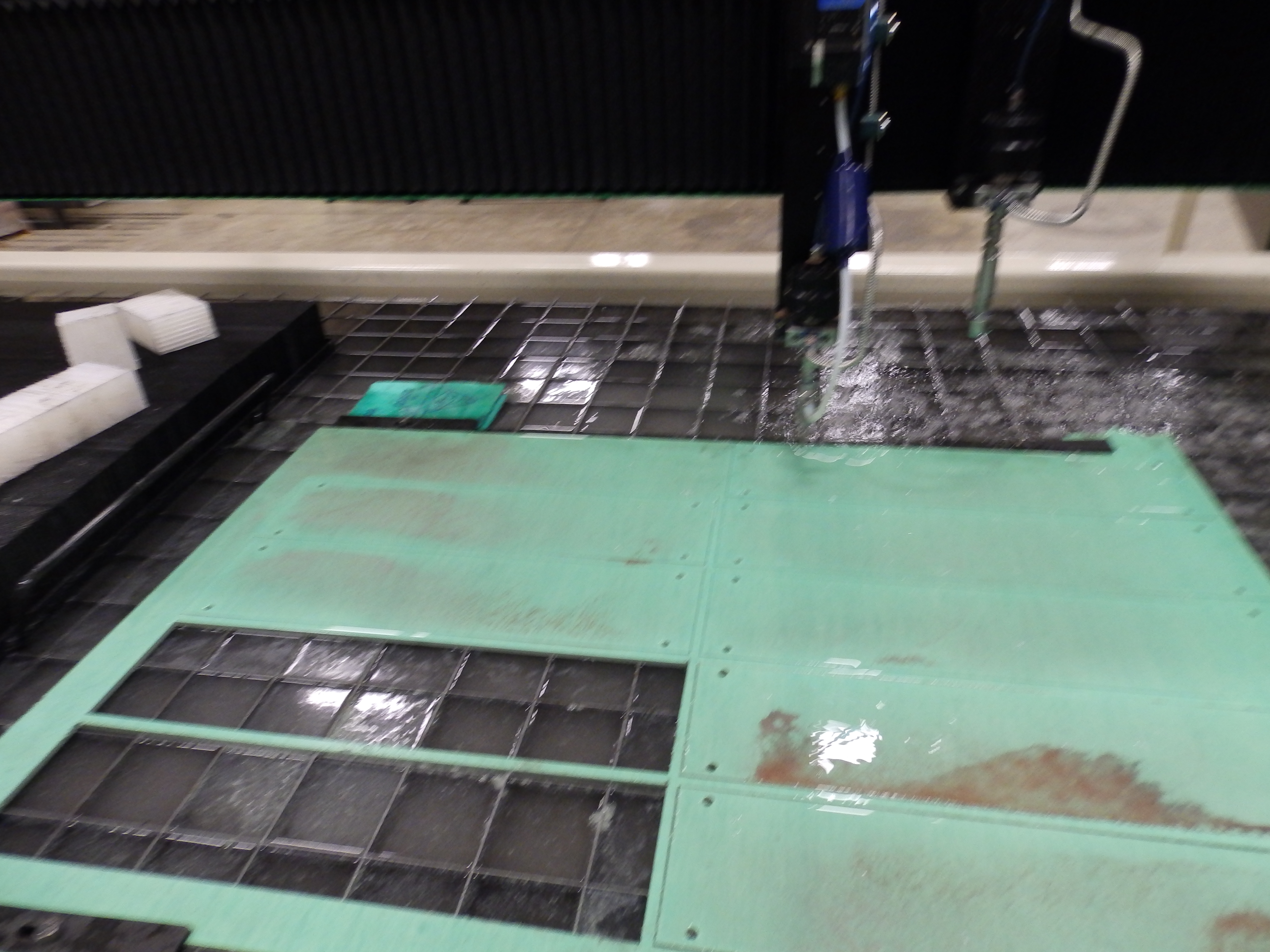

Akron Gasket's WaterJet

Akron Gasket addition of a Ward Jet waterjet machine has opened up many opportunities for us.The 5′ x 10′ cutting area can utilize either a water only or an abrasive cut.

Molded Products

Tolerances:

- RMA Precision Tolerances

Type:

- Compression or Transfer

Materials:

- Neoprene

- Nitrile

- EPDM

- Silicones

- FKM

Extrusions

- Neoprene, Nitrile (Buna N), EPDM, FKM, Silicone

- Neoprene Sponge. Nitrile Sponge, EPDM Sponge, Silicone Sponge

Shapes:

- Solid Cord Stock

- Tubing

- Custom Profiles

Lathe Cut Products

-

- EP Rubber

- Fluoroelastomers

- Natural Rubber

- Neoprene

- Nitrile

- SBR Rubber

- Silicone

- Synthetic “Natural” Rubber

Sizes:

Up to 12″ outside diameter

Tolerances:

RMA Precision Tolerances

Vulcanizing and Custom Fabrication

- Custom Gasket Fabrication from drawing and or Customer samples

- Hot Vulcanizing using standard and injection presses

- Cold Bonding of many different materials

- In house application of Pressure Sensitive Adhesives (PSA) to virtually all materials

- Secondary operations such as shrink wrap packaging and assembly.

Akron Gasket has always been an excellent source for custom gaskets.